roughing end mill depth of cut

They do cut very well - higher feed rates and depths and lengths of cuts - but over-loading or over-speeding will ruin them. Cut Depth 05mm Pf04mm.

WIDIA RUEBIG 2343568 NINA 423048 Center Cutting General Purpose Torus End End Mill 4 mm 7 mm Max Depth of Cut 2 Flutes 6 mm Shank 38 mm OAL.

. Now heres the last piece. Smooth cutting paths without rapid changes in direction or cutting parameters reduce the load on the end mill and improve end mill life significantly With a shallow depth of cut a 45-degree entry angle can yield fine surface finishes limit the generation of burrs at the cut exit and lift chips away from the workpiece to prevent them from marring it. The distance between scallops is referred to as pitch.

Standards Roughers Long Lengths Inch Metric HS Carbide. This means a 050-inch end mill will be engaged 0025 to 0050 inch. End Mill Diameter 18 316 14 38 12 58 34 1 Recommendation for Coated Tools.

The machining time spent roughing your workpiece is mostly determined by Material Removal Rate. TiCN add 40 on SFM. End Mill Speed Feed Calculator.

They are designed to remove large amounts of material quickly and more efficiently than standard end mills. Ad For Taps Dies Cutting and Measuring Tools. I am creating a new calculator based on your feedback.

Profile milling is a common milling operation. Also for the same reason the depth of cut for semi-finishing end mills can be increased. Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use.

End mills are sensitive to the effects of cutting forces. Multifunctional End Mill for High Speed Roughing and Precise Side Milling Work Materials. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material.

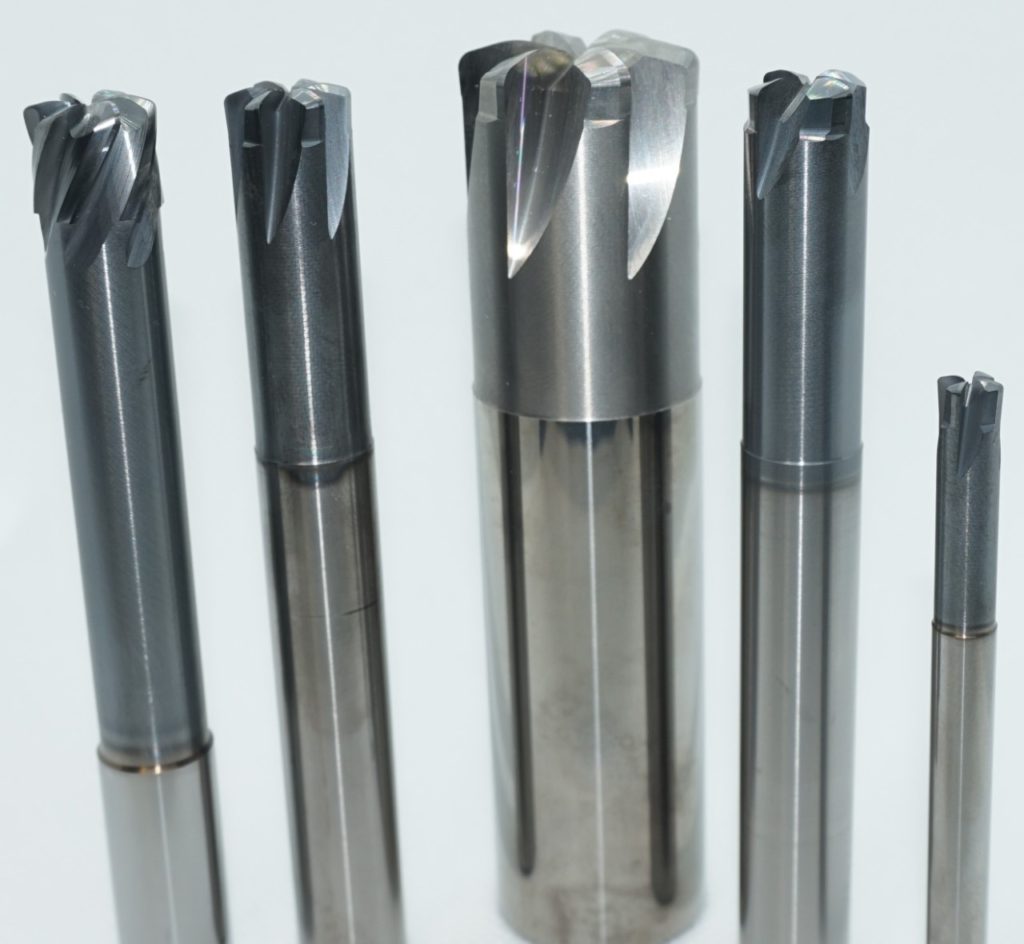

From memory they are about 20mm 0800 and 10mm 38 with a plain spiral-fluted end mill - about 12mm 12 for scale. End Mill Terms A - Mill Size or Cutting Diameter B - Shank Diameter C - Length of Cut or Flute Length. Round inserts and concepts with radius are milling cutters used for roughing and semi-roughing while ball nose end mills are milling cutters used for finishing and super-finishing.

How does roughing end mill work. This is because the cutting resistance is reduced because the chips are broken into short lengths by the wavy cutting edges. Free easy returns on millions of items.

Roughing End Mills - Carbide Cobalt and HSS. Standard depths of cuts for roughing end mills can be set at a larger value than ordinary type end mills. These mills have scallops on the outside diameter which causes the metal chips to break into smaller segments.

MRR Axial Depth of Cut Radial Depth of Cut Feed Rate all values in inches or inches per minute for Feed Rate This formula yields the number of cubic inches per minute your cutting tool is removing. This setting will impact RCT calculations as well. They are designed to remove large amounts of material quickly and more efficiently than standard end mills.

And Axial depth of cut ADOC the distance a tool engages a workpiece along its centerline are the backbones of machining. Normally i would use a depth of cut of 31 to 625 with a 625 dia roughing end mill for a full width slot feeding straight across G1. Machining to appropriate depths whether slotting or peripheral milling profiling.

HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. WIDIA HANITA 5329387 Series Eccentric Rougher 6 Flute Inch Roughing Finishing End Mill 508 mm Max Depth of. Now choose the right surface feet per minute SFM or surface meters per minute SMM Use the SFM and the diameter of the mill to calculate the RPM of your machine.

Carbide Square End Mills. Read customer reviews find best sellers. The axial cutting depth should be generally reduced to around 70 of the edge length.

Here are two of my roughers - aka Corncobs. I was wondering what others normally consider maximum depth of cut ratio to diameter of end mill with a roughing end mill milling cast iron medium hardness. Profile milling process Profile milling covers the.

Free shipping on qualified orders. Radial depth of cut RDOC the distance a tool is stepping over into a workpiece. They are mainly used to rough mill the material off when large amounts of material are removed.

Ad Browse discover thousands of brands. Objective of rough pass is to remove bulk amount of excess material from. This results in lower cutting pressures at a a given radial depth of cut.

Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. Every machining operation entails a radial and axial depth of cut strategy. For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter.

7 rows Roughing Finishing. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM. HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC.

This results in lower cutting pressures at a given radial depth of cut. Choose the proper chip load factor CLF based on the radial depth of cut. For example the average recommended feed rate for a 050-inch tool is approximately 0002 inch per tooth.

This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from. Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segmentsThis results in lower cutting pressures at a given radial depth of cut.

End mill was average length with 15 LOC flute for 58 dia end mill.

4 6 Flute High Feed End Mills Epic Tool

Advanced Roughing Strategies Faster Through Optimized Toolpaths Secotools Com

Selecting The Right Plastic Cutting End Mill In The Loupe

The Secret Mechanics Of High Feed End Mills In The Loupe

Hanzel 5 Things Should Know How To Selecting End Mill

End Mill An Overview Sciencedirect Topics

End Mill An Overview Sciencedirect Topics

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

Kor Series End Mills Dynamic Milling Vs Conventional Milling Youtube

What To Know When Selecting An End Mill End Mill The Selection Machining Process

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

Power Feed From Ingersoll Video In 2020 Cnc Machinist Cnc Programming Cnc Machine

Chipbreakers Vs Knuckle Roughers End Mill Knuckle Rough

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

High Efficiency Roughing Endmill For Difficult To Cut Material 4 5 6rfh Youtube

Speed Feed Recs Melin Tool Company

End Mill Selection Guide By Mekanika Wikifactory